Natural mattresses from 100% natural latex

History

The Latin-American Indians probably already knew about caoutchouc in the 10th century. Christopher Columbus was the first European to encounter this material. In the second half of the 18th century larger amounts of caoutchouc were for the first time shipped to Europe. With the invention of vulcanisation in 1839 through Charles Goodyear caoutchouc – in the form of rubber – became an important ingredient of industry. The caoutchouc boom had begun. In 1876 Henry Wickham managed to export caoutchouc seeds to Ceylon and to establish plantations there. For a few decades Brazil had the trading monopoly for this material. Already at the beginning of the 20th century production in South-East Asia had overtaken Latin-America.

The largest producers of caoutshouc (2005)

Position Country Production (in 1,000s)

| 1 | Thailand | 3.030 | 7 | Ivory Coast | 123 |

| 2 | Indonesia | 1.796 | 8 | Nigeria | 112 |

| 3 | Malaysia | 1.000 | 9 | Liberia | 108 |

| 4 | India | 694 | 10 | Brazil | 96 |

| 5 | China | 550 | 11 | Sri Lanka | 92 |

| 6 | Vietnam | 391 | 12 | Philippines | 88 |

About 70% of the worldwide natural latex production is being used for fabrication of automobile tires. Only a very small percentage flows into the manufacturing of mattresses.

Harvesting

Natural latex is harvested from the resin of the caoutchouc tree (rubber tree, Hevea brasiliensis). This tree grows particularly in South-East Asia but also in other tropical areas. Originally, Hevea brasiliensis comes from South America. To harvest the sap a bow shaped incision is made into the bark of the rubber tree. This way the latex milk can escape and run into small buckets placed to collect it.

The release of the milk is a protective measure by the tree to defend itself against mould and bacteria. Hevea brasiliensis can grow up to 40 metres tall and can get a circumference of up to 35cm. The rubber tree is part of the family of cadelillas or milk bushes. When the tree is 7 years old the first latex harvest can take place. The word caoutchouc is derived from cahuchu (American Indian for crying tree).

Advantages of natural latex

- Natural rubber is a regenerative natural resource (synthetic caoutshouc is extracted from raw oil)

- The high point elasticy from an orthopaedic point of view of proportional body figure in the mattress

- Long enduring, consistent elasticy

- Highly durable

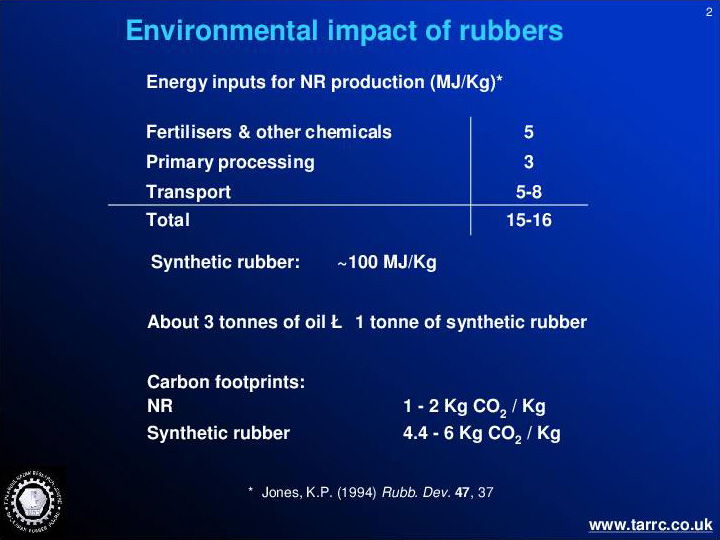

- Vastly smaller energy consumption (around 10-15%) of manufacturing in relation to synthetic latex

- Natural latex is free of solvent, CFC and cancer-causing, chemical substance

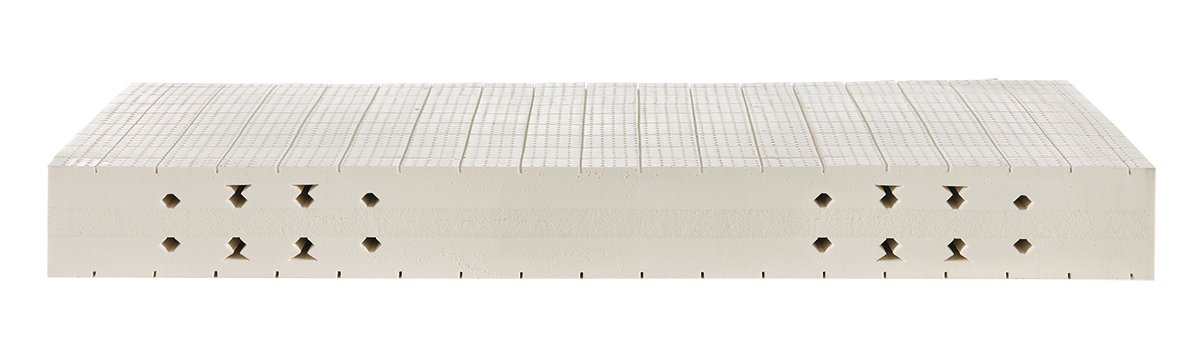

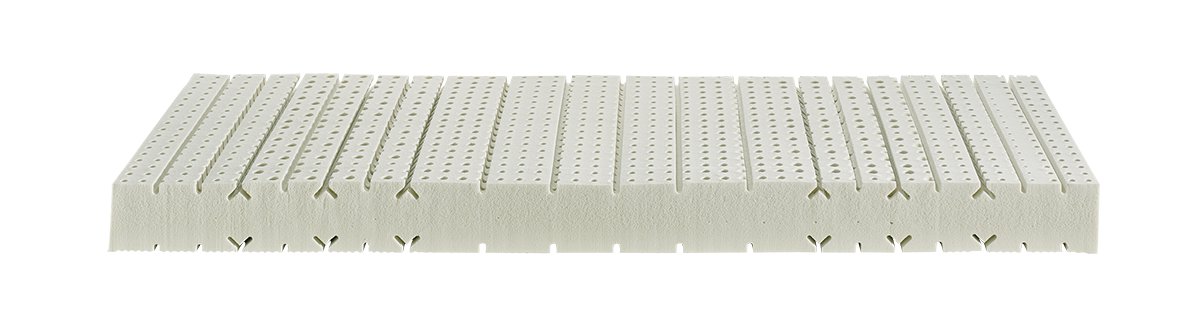

- Breathable due to million little air chambers

- Harvesting by hand, ecological and sustainable

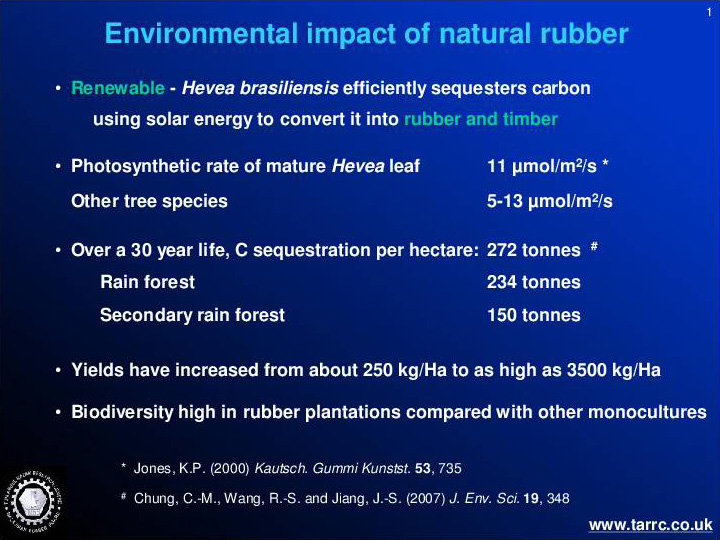

The ecological balance of natural latex

Here is a compilation of the ecological advantages of natural latex – the text is formulated in English.

You can find further information about natural rubber at the homepage of QUL (quality association for environmentally-agreeable latex mattresses e.V.).

Dr. Rüdiger Plänker, Owner and managing director of dormiente GmbH visiting the latex plantations

The fabrication of natural latex cores for mattresses – From raw milk to mattress core

The natural latex used by dormiente originates from Sri Lanka primarily. Here on the plantations the natural latex is extracted and processed to natural latex cores via an elaborate vulcanisation technique, which you can find in your mattress, granting you an inimitable sleeping environment.

The latex milk is being processed to a so-called latex core by an elaborate foaming procedure. In order to reduce the process of vulcanisation to a few hours additives (e.g. sulphur, antioxidants, surfactants, therefore soap for foaming etc.) are added. In nature this process as skin closure would take several months. All ingredients used are non-toxic. At around 100° C the still liquid mass is being vulcanisied and shortly after cooled thereby hardened. This is done in big core forms where the foamed latex milk is infused and “baked” later. Then the latex core is taken out of the form, being washed several times and then dried. Afterwards every form has to be elaborately cleaned similar to a cake tin.